Product Feature

Brand Name: Elom Brand

Output Power: 160kW-15MW

Pole: 4p-40P

Voltage: 400/690V 3000V, 3300V, 4160V, 6000V, 6600V, 10000V, 11000V, 13800V

Protect Feature: IP00, IP23, IP54, IP55, IP56

Cooling method: IC01, IC411,, IC611, IC616, IC666, IC81W, IC86W,IC37

Mounting type: IMB3, IMB35, IMV1, IM7311

Certification: CCC,CE,ROHS,UL,VDE,EAC,ISO9001-2015

EFF: IE2 IE3 IE4

Color: blue or as requirement

Insulation class: F or H

Temperature rise: B or F

Accessory: PT100, PTC, PTO, Space heater, SPM vibration sensors

advantage: high efficiency,low noise good quality ,good performance

applications: Impulse turbine, Reaction turbine

Hydro generator structure and type

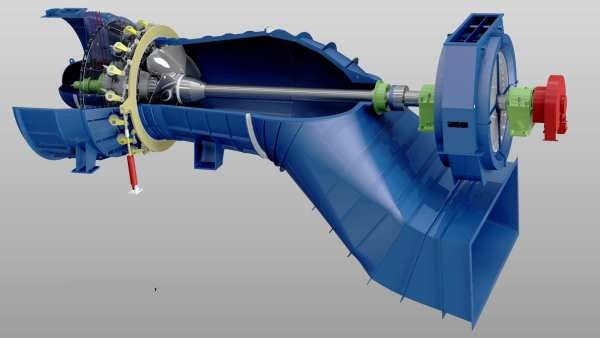

Hydro generator is one of the key products of our company. The generator is composed of rotor, stator, frame, thrust bearing, guide bearing, cooler, brake and other main components. The stator is mainly composed of frame, iron core, winding and other components. The stator core is made of cold-rolled silicon steel sheets, which can be made into an integral and split structure according to the manufacturing and transportation conditions.

The installation structure of hydro generator is usually determined by the type of hydraulic turbine. There are mainly the following types:

Horizontal structure:Hydro generators with horizontal structure are usually driven by impulse turbines. Horizontal water turbine units usually use two or three bearings. The structure of the two bearings has the advantages of short axial length, compact structure and convenient installation and adjustment. However, when the critical speed of the shafting cannot meet the requirements or the bearing load is large, the three bearing structure needs to be adopted. Most of the turbine generators produced by our company are small and medium-sized, with a capacity of less than 10MW.

Vertical structure:Vertical water turbine generator units are usually driven by Francis or axial-flow turbines. The vertical structure can be divided into suspension type and umbrella type. The thrust bearing of the generator located at the upper part of the rotor is collectively referred to as suspended type, and the thrust bearing located at the lower part of the rotor is collectively referred to as umbrella type. Relatively speaking, the suspended results are more convenient for installation and maintenance.

Tubular structure:The tubular turbine generator set is driven by the tubular turbine. Tubular turbine is a special type of axial-flow turbine with fixed or adjustable runner blades. Its main feature is that the runner axis is arranged horizontally or obliquely, and the flow direction is consistent with that of the inlet pipe and outlet pipe of the turbine. Tubular Hydro generator has the advantages of compact structure and light weight. It is widely used in power stations with low water head.

The hydro generators produced by our company are mainly divided into:

Impulse turbine

Impulse turbine is a kind of hydraulic prime mover that leads out the free jet with kinetic energy with the help of special water guide mechanism and rushes to the runner bucket to make the runner rotate and do work, so as to complete the conversion of hydraulic energy into mechanical energy. In the impulse turbine, it can be divided into cut hammer turbine, oblique hammer turbine and double-click turbine according to the different relative positions and working times between the working jet and the runner.

Reaction turbine

Reaction turbine can be divided into Francis turbine, axial turbine, diagonal turbine and tubular turbine. In the Francis turbine, the water flows radially into the water guide mechanism and axially out of the runner; In the axial flow turbine, the water flows into the guide vane radially and into and out of the runner axially.

In an inclined flow turbine, water flows radially into the guide vane and into the runner in a direction inclined to a certain angle of the main shaft, or into the guide vane and runner in a direction inclined to the main shaft. The working principle of reaction turbine is to weld two or more outlet curved pipes at the lower end of a conical cylinder. The conical cylinder can rotate freely around the central vertical axis and fill the cylinder. When water flows out of the lower curved pipe, it will produce acceleration along the water flow direction. According to Newton's third law, water is used on the curved pipe with the force in the opposite direction.

Turbine application

Pump turbine is mainly used for pumped storage power station. When the load of the power system is lower than the basic load, it can be used as a water pump to use the excess power generation capacity to pump water from the downstream reservoir to the upstream reservoir and store energy in the form of potential energy; When the system load is higher than the base load, it can be used as a water turbine to generate electricity to adjust the peak load.

Therefore, pure pumped storage power station can not increase the power of power system, but can improve the operation economy of thermal power generation units and improve the overall efficiency of power system. Since the 1950s, pumped storage units have been widely valued and developed rapidly all over the world.